The tiller is looking good. Jen sanded it down and is going through the teak cleaner process. Next we’ll dig out all of the rot and fill it with epoxy. Then finish it with varnish or oil, not sure which one yet.

Author:

Windlass Update

The windlass is pretty much back together. I still need to re-tap some bits that were deformed from the beating it took to get the thing apart.

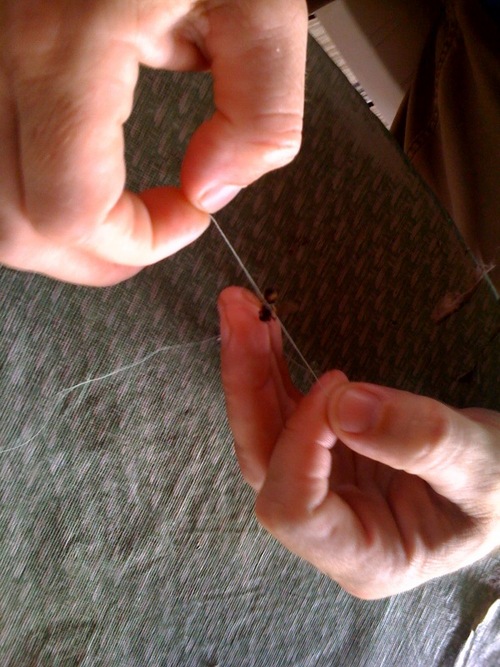

I made up some springs that seem to be working ok. The picture below is the test spring I made. I cut it short and stretched it a bit at a time until the ratcheting action felt right. 100mm seems to be about it. It’s still not perfect but it’s at least working now.

West System Publications

Just a warning:Â This is a bit boat-geeky so you can skip on past if you aren’t doing or planning on doing any fiberglass work.

The West System people publish some really good articles and manuals at westsystem.com. Their search is ok, but google is better. Try copying this into google to browse through everything:

site:http://westsystem.com/ filetype:pdf

Add a keyword or two like this:

blisters site:http://westsystem.com/ filetype:pdf

to search for a specific topic.

I have beaten the mechanical oppressor!

Finally! Got the shafts out of the seized windlass. It’s been about three weeks since I got the thing and I’ve spent way too many days trying to beat, pound, pull, and press the shafts out. Victory!

Now I need to make up some replacement springs and clean everything up and it should go back together and bring joy to our anchor heaving times for years to come.

For those of you wondering why this was so difficult and how it finally happened: The shafts are all held in place by Teflon bushings which makes heating the thing up a bit hairy. The housing isn’t square in relation to the gears so the gears need to be braced before any serious force can be applied. That housing is cast aluminum which makes any hard impact feel like it’s about to crack the thing in half and the shafts are brass which means they squish if you use anything harder than brass to try to pound them out. Weeks and cans of pb blaster, the sacrifice of a few tools, a strained friendship or two, some carefully applied heat, and finally just hitting the fucking thing hard enough made it happen. All that to replace two springs.

Happy Time.